History

TIBITÓ CHOCOLATE is a Colombian Bean to Bar manufacturer established in 2015.

TIBITÓ was born out of a desire to explore the richness and diversity of Colombian cocoa. This curiosity led us to embark on a countrywide journey to source Colombia's finest cocoa beans.

By working with the very best growers, we have achieved a superior product that gives local cocoa producers the credit they deserve. We engage directly with the cocoa farmers and cooperatives (with no intermediaries) to ensure we obtain top-quality beans while compensating our producers with a premium price for their excellent product.

We have created world-class artisanal chocolate that represents the richness and variety of Colombian regions and their cocoa beans. At our factory in Bogotá, we carefully process the cocoa beans with state-of-the-art machinery to create the product that we love so much – and we hope you will too!

TIBITÓ CHOCOLATE is a wonderful adventure through Colombian cocoa's flavors, aromas, and textures. We are delighted to share this journey with you!

PRODUCTION PROCESS

AtTIBITÓ,our passion drives us to produce the best artisan chocolate. Ensuring high quality and the best flavor requires meticulous attention to detail and rigorous production processes, beginning with harvesting, fermentation, and drying of the cocoa beans, up to the molding and packaging of each chocolate bar produced by our master chocolatiers.

We work hand in hand with the different regional growers in Colombia to ensure we obtain the best beans available. During this process, we verify that the farmers have optimized the fermentation of the beans, which is an essential step to achieving the best flavor in ourTIBITÓ,bars. Furthermore, to fairly compensate the people who plant and produce the best fine flavor cocoa, we buy cocoa at premium prices directly from farmers and cooperatives.

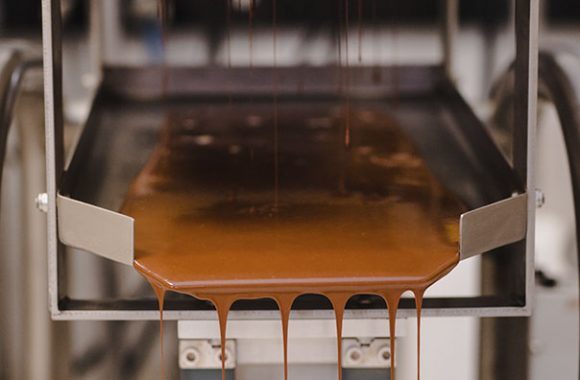

Once the cocoa beans arrive at our plant in Bogotá, Colombia, we begin the roasting process set with specific parameters to bean to bring out the best flavors of each regional cacao. We then crack and winnow the beans to separate the cocoa nibs from the skin and then grind the nibs until it has transformed into warm liquid cocoa liquor. Afterward, we temper the liquor until the silky smooth texture, and shiny surface characterized by ourTIBITÓ,chocolate is obtained.

HOW DO WE MAKE OUR CHOCOLATE?

STEP 1 RECEIVING AND QUALITY CONTROL OF THE BEANS:

After receiving the cacao beans in our factory, we begin evaluating, cleaning, and selecting only the perfect beans. For our fine flavor Tibitó chocolate, we verify the cocoa bean's fermentation has been optimal. This step is crucial to guarantee we produce high-quality chocolate.

STEP 2 ROASTING

After selecting the best beans, we start the roasting process. The roasting temperature and time vary by the bean's natural characteristics like type, size, and humidity. This step is crucial to reduce moisture and bacteria in the bean and develop the flavor.

STEP 3: CRACKING AND WINNOWING

The cocoa bean is broken into small pieces during this process, and the shell is removed from the nib. For the chocolate-making process, only the nib is used. However, the shell is held aside and used to make compost, an organic garden fertilizer.

STEP 4: GRINDING

The cocoa nibs are ground into a thick paste called cocoa liquor through constant movement, friction, and heat. This process takes approximately 7 hours for each batch of 13 to 15 kilograms of roasted nibs. The liquor is our essential raw material. It is stored for 2-3 months in order for the aromas and flavors to mature.

STEP 5: REFINING AND CONCHING

During the refining and conching stage, we add additional ingredients such as cocoa butter, sugar, or milk to the cocoa liquor. This process takes about eight hours.

STEP 6: SIFTING

During this stage, we sift the finished chocolate through vibrating screens to eliminate any cocoa particles or unrefined sugar. As a result, we have chocolate with a silky and smooth texture.

STEP 7: TEMPERING AND MOLDING

In the tempering machine, the cocoa butter crystals become aligned. This process makes our bars hard and shiny and raises the melting temperature. Once tempered, the chocolate is poured into the mold; then, the mold is tapped against a rigid surface to remove any air bubbles.

STEP 8: WRAPPING

Last but not least, we take our cooled and solidified bars out of the molds, and after a careful quality control inspection, we wrap them by hand with wrapping paper. Our packaging is inspired by the simplicity and elegance of Japanese culture and is made with FSC-certified paper. FSC stands for Forest Stewardship Council, an organization that works to promote the practice of sustainable forestry worldwide.

OUR TEAM

GUSTAVO PRADILLA

Founder

MARTA LUZ BRAVO

Sales Director

MARCELA BONILLA RUBIO

CHOCOLATE MAKER-PASTRY CHEF

Marcela Bonilla Rubio is a chocolate maker and pastry chef with more than 10 years of experience in the gastronomic industry. In July 2023 she assumed the position of Head of Production at TIBITÓ chocolates. Between 2020 and 2022 he was Lead Chocolatier at “The Xocolate bar” in Berkeley, California. During her stay in the United States, she strengthened her knowledge of ganaches and chocolate fillings at the “Ecolechocolat” professional school for chocolatiers and at the “Melissa Coppel” workshop. Between 2018 and 2019 she studied at the “Instituto Gato Dumas” in Bogotá, where she obtained the Gold Medal in his pastry cohort and was part of the GATO DUMAS LAB with the GD -Method project. In 2014 she founded the pastry shop “La ceiba” in the La Macarena gastronomic neighborhood of Bogotá. During its four years of operation it was characterized by its excellent service and the quality of its products. She complements her work, advising and giving consultancies in chocolate and confectionery, in addition to continuing exploring with her personal project ¨cacaomasse¨.

Our production assistants and the excellent administrative team support us in an exceptional way in our daily tasks.